HEAT EXCHANGERS

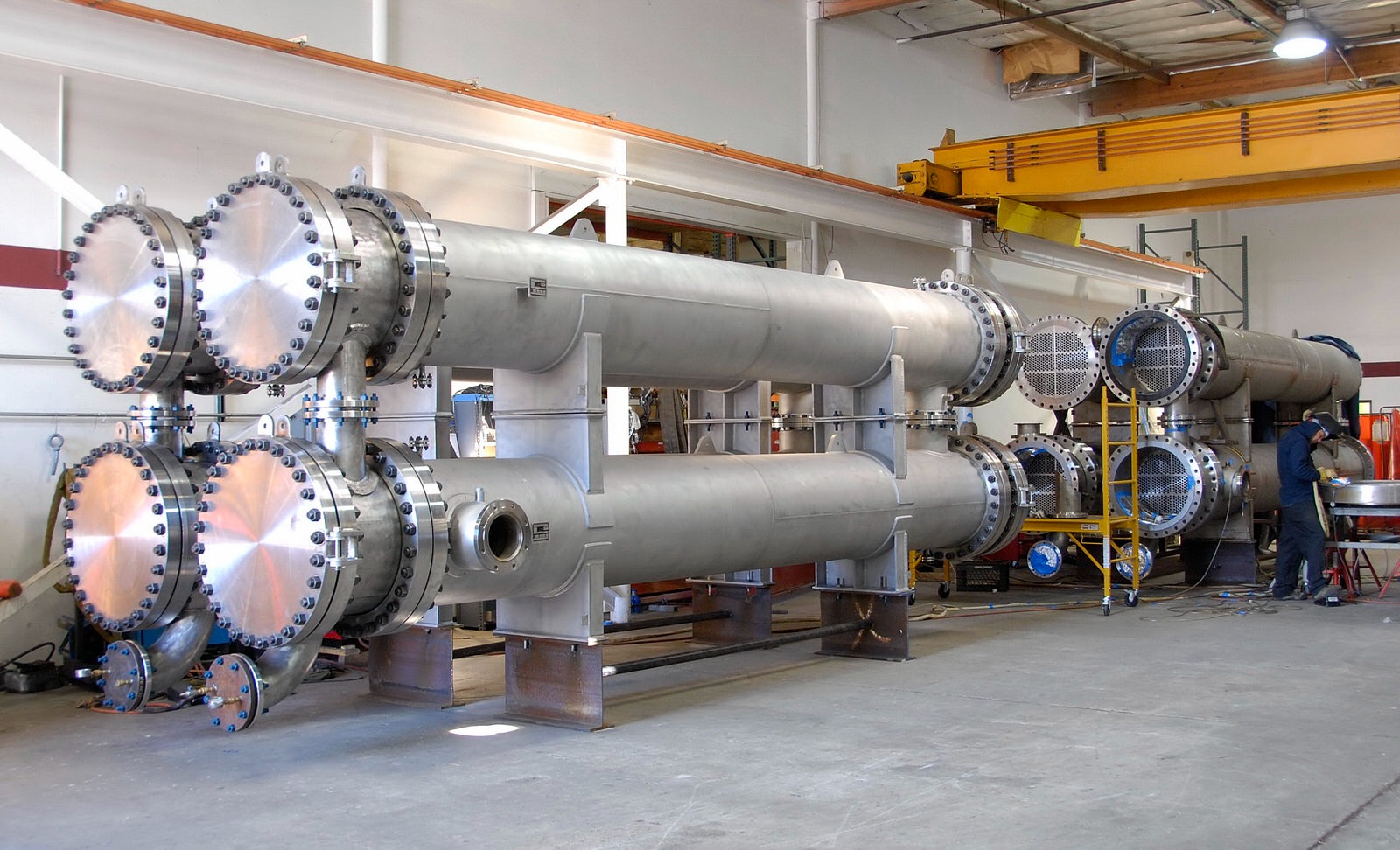

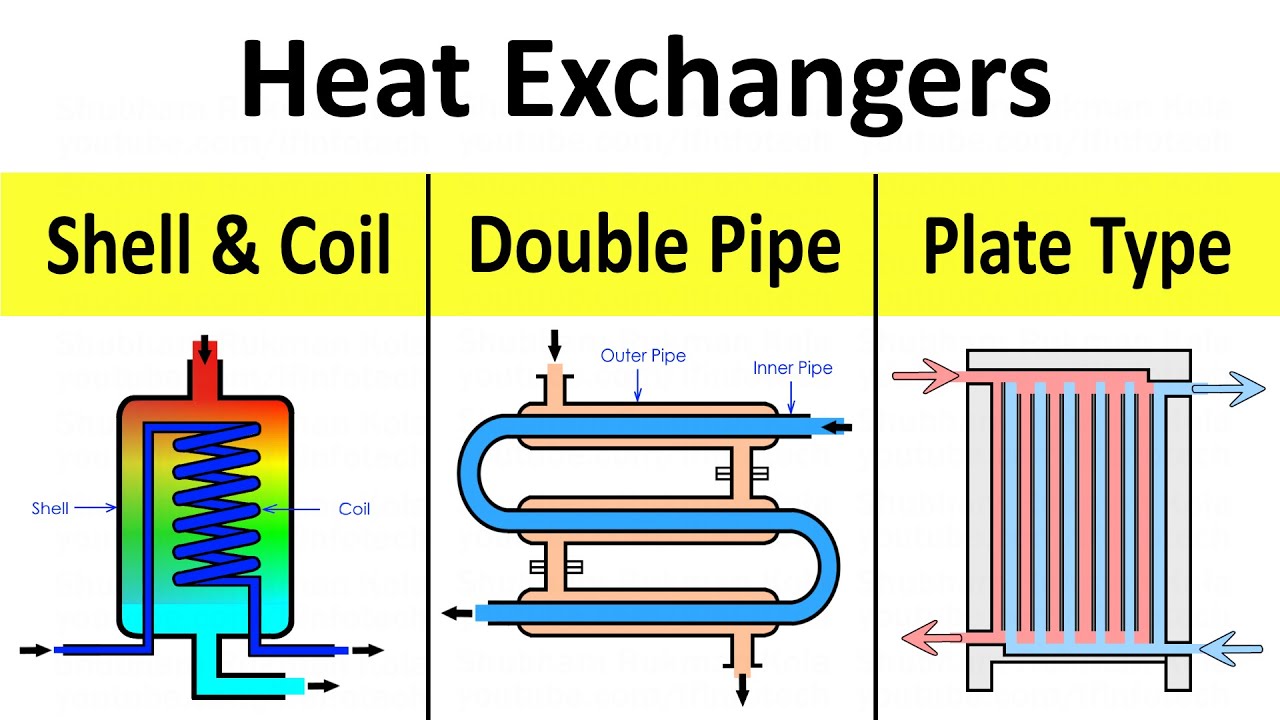

According to customer request and process information, heat exchanger pipe bundles are manufactured from carbon steel, stainless, copper, brass and bafon pipes. Pipe diameters vary from 8mm to 42.3mm. Fluids are used to determine pipe diameters. Pipe bundles, which are made with straight or U pipes according to the fluid types and the design model of the heat exchanger, are designed by considering the most common calcification and corrosion. The preferred system in steam systems is the “U” pipe system. In oil systems, one side is fixed and the other side is a straight pipe system with a floating mirror. The point to be considered here is the selection of suitable gaskets for sealing.

Tubular Heat Exchanger Usage Areas

The heat exchangers, which are used in the main main sectors such as textile, ship and food, can be used in all sectors where a second alternative energy need arises in an alternative energy. In companies with steam, hot oil boiler and hot water boiler, low pressure steam demand for utility water and/or hot water etc. It offers economical solutions to meet the needs. U and straight tube heat exchangers provide ease of process if cleaning factors are taken into consideration in energy recovery applications and waste water recovery systems in the textile sector.

Main usage areas of heat exchangers

* Liquid-Liquid

* Water-Oil

* Water-Gas(air, nitrogen etc.)

* Steam-Water

* Steam-Oil

* Steam-Gas

* Oil-Oil

* Oil-Gas

MULTIHEAD WEIGHER

MULTIHEAD WEIGHER